Automation in Dispatch using QR code for Finished products

I am very proud to share today that we just completed "Automation in dispatch process using QR code to achieve Zero tolerance at our manufacturing customer.

We have recently implemented “Automation” in dispatch process for finished Goods using QR codes at our manufacturing customer . The end to end process is designed and developed in ERPNext.

Volume of dispatch at Manufacturing client is from 1000 Boxes to 1200 Boxes / Day.

Objective:

The goal was to create a vision where there should be no “Manual Data Entry” in ERP, throughout the whole dispatch process. We wanted to achieve:

- Accuracy in Dispatch

- Automating Invoice generation after material loading in Truck

- Avoid wrong item, Quantity, incorrect Batch

- Avoid customer returns

ERPNext Process:

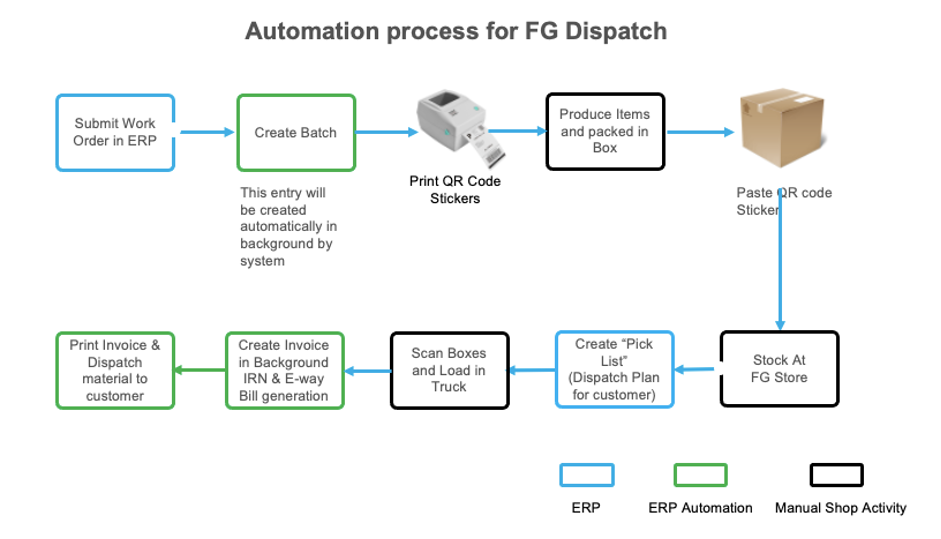

As part of the daily production plan, the process is to create a work order for the finished goods and take the print of QR code stickers. These stickers will be issued to the Production department, which they will paste on each box. Once the production is completed, boxes are stored at Finished Goods store.

For the dispatch plan, we used “Pick List” functionality for each customer. On the pick list, we have provided QR code scanner which will be used to scan the Box and pick the item quantity.

Once “Pick List” is completed, operator can submit the pick List. We have automated the process to create Sales Invoice, IRN generation and E-way Bill creation through system based on the Pick List quantity.

Challenges :

After completion of development, we started implementation of QR codes scanning on the shop floor. We observed that Scanning QR codes taking long time. Existing QR code library was not auto focusing on QR code. So we tried with Bluetooth QR code hand-held devices, but no success.

Solution:

We tried with web based QR code scanning library of "Dynamsoft" ( https://www.dynamsoft.com/barcode-reader/overview/ ) which worked and speed with Beep sound ensured that QR code is scanned.

Benefits:

- No hardware investment required, since application is web based and works on any mobile devices.

- Accurate despatch of Item and Quantity achieved.

- Any person can just scan the Box using mobile phone - No person dependency

- Mismatch of dispatched Quantity and Invoice quantity matched.

- Time saved in Invoice creation process - Invoice created after Picklist submission.

Deployment :

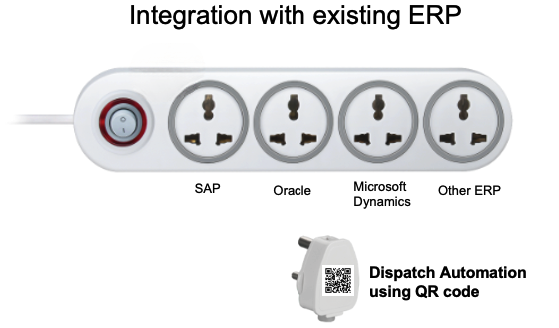

This tool is deployed on ERPNext and also it can be integrated with any existing ERP like SAP ECC, S4HANA, Oracle or any other current ERP.

Conclusion:

Using this automation, any labour can scan QR code on boxes and work in this area. No skills/training is required for users.

If you need any more information, please contact satish@vedarthsolutions.in

----- End of Article--------

About Author:

Satish Aralkar (Founder – Vedarth Solutions) is SAP consultant having 15 years of SAP implementation and 12 years of Domain experience in manufacturing domain. Currently working on ERPNext implementations, Automation and Digital Transformation.

Amazing achievement.. 👍🏻👍🏻 Congratulations !!!

Gr8 achievement, Satish. Congratulations 🥳

Excellent Achivement.